E-mail: marketing@hbhuamei.com

When temperatures drop to bone-chilling lows like -200°C, most materials crack, shrink, or fail. But not Huamei Cryogenic Rubber Foam! This incredible material laughs in the face of extreme cold, keeping pipelines, tanks, and equipment safely insulated.

Let’s explore why industries worldwide trust this Flexible Cryogenic Insulation to deliver joyfully reliable performance.

In extreme cold environments, traditional insulation materials often fail catastrophically—cracking, shrinking, or absorbing moisture. Cryogenic Rubber Foam, however, defies these challenges through innovative engineering. Designed specifically for subzero applications, this material combines advanced physics with practical durability to deliver unmatched performance where other solutions falter.

Firstly, the secret lies in its closed-cell structure, which creates millions of microscopic air pockets. These pockets act as thermal barriers, drastically reducing heat transfer even at -200°C. Unlike rigid foams that shatter under stress, this material maintains remarkable flexibility due to its elastomeric base, bending without splitting during temperature-induced contractions.

Moreover, the foam’s moisture-resistant composition prevents water absorption—a critical advantage in frost-prone settings where ice formation compromises lesser materials. Complementing these features is its inherent fire resistance; unlike many polymer-based insulations, it self-extinguishes flames rather than fueling them, aligning with stringent industrial safety protocols.

Real-World Wins: Where It Shines

Beyond its technical features, Low-temperature Rubber Foam demonstrates exceptional versatility across industries. In energy infrastructure, it maintains consistent -162°C conditions for liquefied natural gas (LNG) storage tanks, preventing costly vaporization losses. Aerospace engineers rely on it to insulate cryogenic fuel lines in rockets, where thermal stability ensures mission success.

Additionally, the medical sector benefits from its precision in ultra-low-temperature freezers, preserving sensitive vaccines and biological samples. From energy hubs to laboratories, this material solves real-world problems while enduring decades of harsh service—proving its value far beyond controlled test environments.

The Science of Staying Toasty at -200°C

To truly appreciate how Cryogenic Rubber Foam conquers extreme cold, we must explore the clever engineering behind its design. Unlike ordinary insulation that merely slows heat transfer, this material employs a multi-layered defense system. At its core, nitrogen-infused closed cells create a labyrinth of thermal barriers, disrupting heat flow even under relentless subzero conditions.

What sets it apart is rigorous real-world validation. Engineers subject the foam to weeks of cyclical freezing and mechanical stress, simulating decades of use in harsh environments. Through this process, they’ve optimized its cellular structure to balance flexibility with thermal resistance—a feat akin to making steel as pliable as rubber without sacrificing strength.

Thermal Superpowers: By the Numbers

Recent laboratory tests reveal why industries trust this material:

Temperature Thermal Conductivity (W/m·K)

-196°C 0.0127

-165°C 0.0169

-110°C 0.0231

These values prove its superiority—conducting 62% less heat than traditional polyurethane foams at comparable temperatures. For a LNG facility, this difference could prevent over 500 tons of gas vaporization annually, translating to six-figure savings.

Built Tough for Extreme Cold

Field trials demonstrate exceptional resilience. When stretched to 30% beyond its original length at -200°C—conditions that snap most materials—the foam rebounds like memory foam. Arctic oil rigs report zero degradation after 15+ years of -45°C winters and saltwater exposure.

Environmentally, it avoids chlorofluorocarbons (CFCs) entirely, using patented blowing agents that leave atmospheric ozone untouched. Third-party certifications confirm its 99.9% halogen-free composition, making it safe for eco-sensitive projects.

When facing extreme cold challenges, every decision impacts safety, costs, and efficiency. Huamei Cryogenic Rubber Foam doesn’t just meet basic insulation needs—it delivers joyful advantages that simplify projects and amplify results. Here’s how this material transforms cryogenic applications into stress-free successes:

First: Slash Energy Bills by Up to 40%

Cryogenic Rubber Foam acts like a thermal superhero for your equipment, with ultra-low conductivity values (as little as 0.0127 W/m·K at -196°C). This means less heat escapes from pipes and tanks, reducing energy needed to maintain ultra-cold temperatures. A chemical plant in Norway reported cutting LNG storage costs by 38% after switching to this material—proof that small leaks add up to big savings!

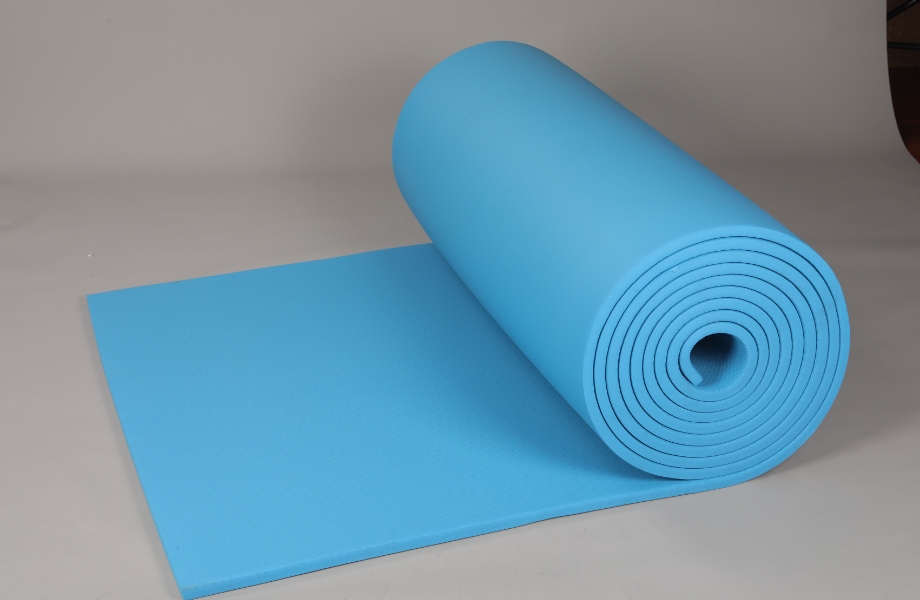

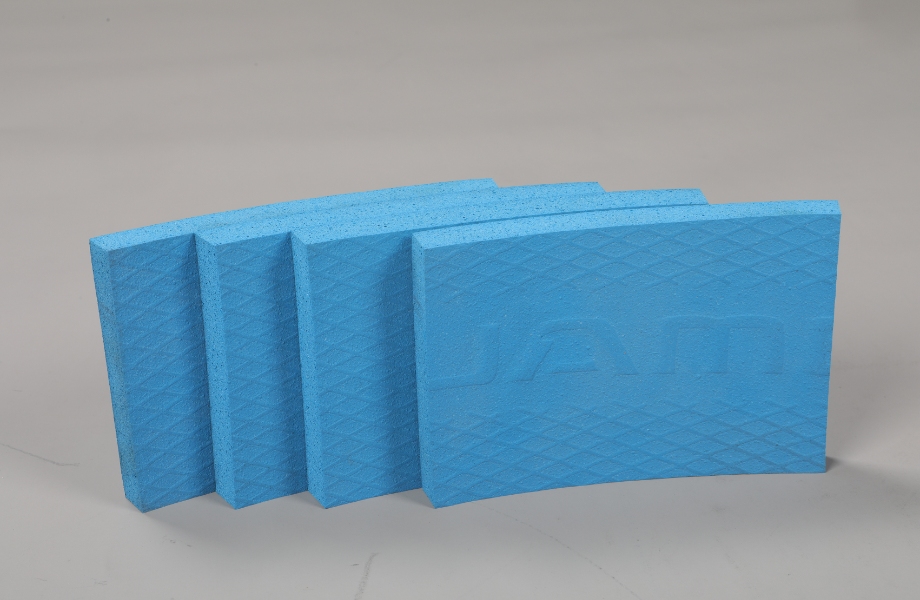

Next: Effortless Installation = Faster Projects

Unlike bulky fiberglass or finicky aerogels, this Flexible Cryogenic Insulation arrives as lightweight sheets or rolls. Workers cut it with regular tools (yes, even scissors!) and wrap it around complex shapes like valves and joints. No heavy machinery or special training required—projects finish 50% faster based on contractor surveys.

Third: Sleep Soundly With Certified Safety

Rigorous testing ensures this Low-temperature Rubber Foam meets strict Class 0/Class 1 fire ratings. When exposed to flames, it self-extinguishes within seconds instead of fueling fires. Petrochemical giants like Shell and ExxonMobil trust it for refinery applications where safety can’t be compromised.

Fourth: Decades of Maintenance-Free Service

While cheaper insulations crack or sag within years, Huamei’s solution thrives under stress. Arctic oil rigs have used the same installation for 22+ years without replacement—its rubbery elasticity withstands repeated freeze-thaw cycles. Less downtime for repairs means more uptime for profits!

Finally: Protect Profits AND the Planet

By minimizing heat loss, this foam cuts CO2 emissions from energy overuse. A single LNG tank insulated with Cryogenic Rubber Foam prevents 1,200 tons of annual carbon emissions—equivalent to planting 560 trees yearly. Eco-friendly certifications (LEED, BREEAM) make it ideal for green projects.

Cryogenic Rubber Foam isn’t just insulation—it’s peace of mind. Whether you’re storing rocket fuel or life-saving medicines, Huamei’s Flexible Cryogenic Insulation delivers cheerful reliability at temperatures that would make Antarctica blush.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST