E-mail: marketing@hbhuamei.com

In this article, we will focus on rigid foam insulation for interior wall applications, comparing three popular types.

Expanded polystyrene (EPS)

Extruded polystyrene (XPS)

Graphite polystyrene (GPS)

Expanded polystyrene insulation, commonly known as EPS, is a closed-cell insulating material that has been around since the 1950s. EPS is made from 98% trapped air and only 2% plastic, making it an efficient insulator using a small amount of raw material.

Expanded polystyrene is versatile because it can be moulded and cut into different shapes. The most common shape for retrofit and new construction applications is flat, but contoured EPS has also become popular in insulating vinyl siding. Contoured EPS can be used not only as an insulating material but also to improve the durability and impact resistance of the siding.

Energy efficiency is a key feature for any insulation material. The energy efficiency of an insulation product is measured by its "r-value" or resistance to heat flow. the higher the R-value, the higher the insulation capacity. the average r-value of EPS insulation is 3.6 per inch. When certain types of plastic finishes are applied, laminates can have an r-value of up to 3.8 per inch.

In addition to providing energy efficiency, EPS without lamination has a perm rating of up to 5.0. The perm rating is a measure of a product's ability to allow water vapour to pass through it.

The average family of four produces between 4 and 6 gallons of water vapour per day. Products with a higher perm rating allow steam to escape to the outside, eliminating the possibility of moisture damage. In terms of cost, EPS typically has the lowest price tag of the three insulation types outlined in this article.

Foil-Clad XPS

Expanded polystyrene, or XPS for short, is a closed-cell insulation product commonly used in remodelling and new construction applications. Due to the manufacturing process, XPS insulation is usually only available in standard-size square or rectangular panels.

Just like EPS, energy efficiency is a key feature of XPS insulation. Due to its physical properties, XPS has a higher r-value than EPS, at 4.7/inch.

In the past, XPS manufacturers have been able to claim R-values close to 5.0 per inch, however, it is known that the blowing agent used in the manufacturing process will run out over time, reducing the insulation value. Manufacturers are now reporting the long-term thermal resistance (LTTR) of their XPS products to account for the reduction in R-value over time.

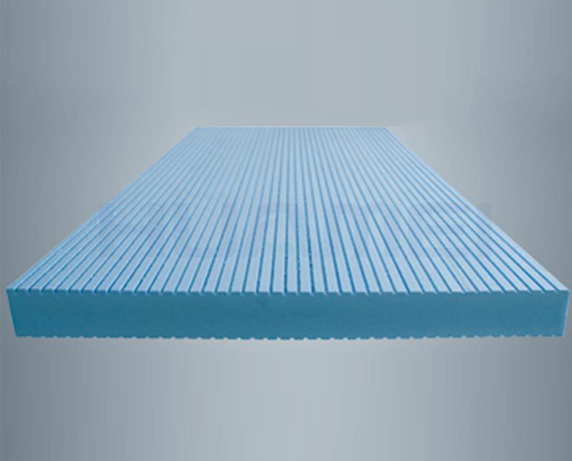

XPS offers higher stiffness and rigidity, making it suitable for roofing, underground, floor slab and other applications.

XPS Panel

Graphite polystyrene insulation, or GPS, is made from Neopor beads, patented and manufactured by BASF. Neopor gives GPS insulation a dark gray appearance and higher r-value than traditional EPS insulation products. Click here to learn more about Neopor.

Similar to expanded polystyrene, GPS can be formed into many different shapes during the manufacturing process. Although GPS is relatively new in the United States, it has become the leading form of insulation in Europe over the last few decades.

The main feature of GPS (Neopor) insulation is the r-value of 4.7 per inch, which is achieved due to the high purity graphite injected into the cell structure of the insulation. Conventional EPS saves energy due to the air pockets in the insulation, which slow down the warm air as it moves towards the cold air. This is what gives it its energy-saving properties.

When radiant heat passes through GPS insulation, it is reflected hundreds of times along the way due to the graphite particles, which significantly slows down the transfer of heat and makes the insulation more energy efficient. When certain types of plastic panels are applied, GPS can achieve R-values of up to 4.9 at one inch.

In addition to providing energy efficiency, GPS insulation without a film finish has a perm rating of up to 5.0, depending on its manufacturing density. The perm rating is a measure of a product's ability to allow water vapour to pass through it.

GPS insulation is more expensive than EPS because of the increased energy savings, but is generally cheaper than XPS insulation.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST