E-mail: marketing@hbhuamei.com

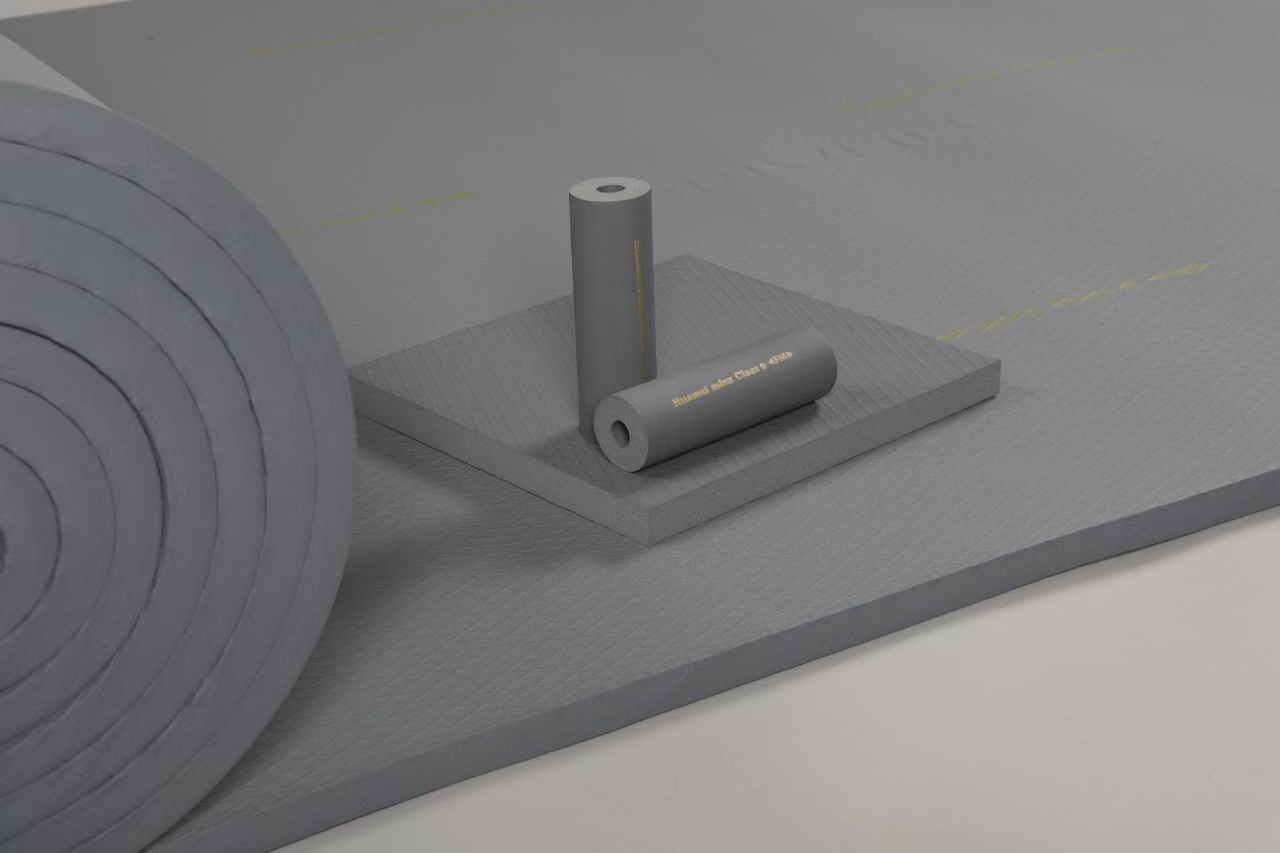

Rubber foam is an elastic material with a porous structure made from a rubber matrix by a physical or chemical foaming process, which allows obtaining foams with different densities and pore structures for different applications.

This material is widely used in many industrial and daily applications due to its properties such as durability, thermal and acoustic insulation, and excellent cushioning properties. In this article, we will help you choose the right rubber foam for you from four aspects: properties, types, uses, and considerations of rubber foam.

1. Cushioning properties

Rubber foam has good elasticity and flexibility and can be quickly restored to its original state after being subjected to pressure or deformation. This makes it ideal for applications that require cushioning and shock absorption.

2. Thermal and acoustic insulation

The porous structure of rubber foam gives it excellent thermal and acoustic insulation properties. It can effectively reduce heat conduction and sound transmission and is commonly used in building insulation and soundproofing panels.

3. Waterproof and durable

Rubber foam is usually waterproof and resistant to chemicals and corrosion. This makes it suitable for outdoor and humid environments.

4. Lightweight

Due to its internal porous structure, rubber foam material is very lightweight, which makes it easy to handle and install without adding weight to the building or equipment.

1. Building and home

Used for thermal and acoustic insulation, floor cushioning, furniture padding materials, mattresses, etc. For example, rubber foam floor mats and acoustic panels are widely used in homes and commercial buildings.

2. Automotive Industry

Used for automotive seat padding, interior parts, sealing strips, shock-absorbing pads, and so on. Rubber foam provides comfort and sound insulation in automobile interiors while preventing wind and rain from entering the car in sealing strips.

3. Sports & Leisure

Used in sports equipment, diving suits, protective gear, etc. For example, neoprene foam is commonly used in the manufacture of diving suits to provide thermal insulation and waterproof performance.

4. Packaging & Logistics

Used for anti-vibration packaging materials, protective cushioning, etc. The cushioning properties of rubber foam make it ideal for the transportation and protection of electronic products and fragile items.

1. Physical foaming

Physical methods (e.g., adding gas) are used to form a foam structure from rubber materials. It is commonly used to produce foam products with a stable and uniform structure.

2. Chemical foaming

Chemical blowing agents (e.g., AZO) are used to form gas in the rubber matrix to produce a foam structure. The temperature and pressure of the foaming process can be controlled to obtain foams with different densities and pore structures.

1. Density

Select the appropriate density according to the needs of the application. Higher-density foams usually have better load-bearing capacity and durability.

2. Temperature resistance

Certain application scenarios require high or low-temperature resistance, so a suitable rubberized foam material should be selected, such as high-temperature insulating glass wool.

3. Chemical resistance

When used in environments exposed to chemicals, rubber foam materials with good chemical resistance need to be selected.

Rubber foam is a multifunctional material that plays an important role in many fields. Choosing the right type and size of rubber foam can significantly improve the performance and service life of your product. If you are looking for the right rubber foam, click here to see Huamei's different rubber foam products with detailed specifications and applications. Committed to excellence and innovation, Huamei offers a wide range of customized foam rubber products to meet the diverse needs of industries such as construction, HVAC, and automotive. Their expertise in manufacturing ensures quality and reliability, making them a trusted partner for insulation solutions worldwide.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST