E-mail: marketing@hbhuamei.com

Insulation is an important component that must be specified when designing functional, cost-effective, and energy-efficient buildings. One way to insulate a building is to install 50 to 152 mm (2 to 6 inches) of rigid foam insulation on the outside of the wall framing. The two most frequently installed types of rigid foam insulation are expanded polystyrene and extruded polystyrene (EPS and XPS). Both have the same basic function: to provide a way to manage the passage of heat through a building system. However, they differ in important ways. Next, the XPS panel supplier will share them with you.

The primary responsibility of any insulating building material is to provide positive thermal performance. However, this is not the only factor to consider when specifying rigid foam insulation. It is also critical to understand how it will perform in several situations.

The different manufacturing processes for the two types of polystyrene insulation may have a dramatic impact on the long-term performance of both products.

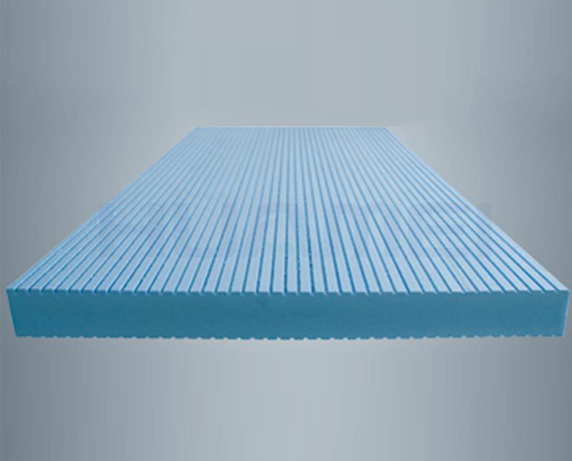

XPS Panel

Extruded polystyrene insulation or XPS insulation is manufactured through an extrusion process. The manufacturing process involves melting together plastic resins and other components. The resulting liquid is then extruded continuously through a die and expanded during cooling. This produces closed-cell rigid insulation.

Foamed polystyrene insulation or EPS insulation is manufactured using a mold to hold small foam beads. Heat or steam is then applied to the die, which causes the small beads to expand and fuse together. This manufacturing process does not create closed-cell insulation because there are usually voids between each bead where they do not come into contact with each other.

Briefly, XPS is manufactured using a continuous extrusion process that produces foam insulation in closed-cell form. EPS, on the other hand, is made by expanding spherical beads in a die and then using heat and pressure to fuse the beads together.

The interconnecting voids between the beads in EPS allow water to penetrate. Since water is a good conductor of heat, this will reduce the insulation performance. This is especially true for underground insulation and inverted roofing applications where the insulation is exposed to water. Also, be aware of climates with temperatures below the freezing point. Freeze-thaw cycles in these areas will cause the water in the voids to expand and break the bond between the beads, which will further reduce the insulation performance. This will open up the EPS insulation. Due to the closed-cell structure of the XPS panel.

The thermal conductivity of XPS starts at a lower level than that of EPS. This is because air is a good conductor of heat. interconnected voids in EPS foam conduct heat due to the air inside, so you need a higher density (more beads, so fewer voids) to reduce this form of conduction.

EPS has a poorer compressive strength than XPS. In order for EPS to achieve the same compressive strength as XPS, the density of the foam will need to be higher, thus requiring a more laborious manufacturing process.

If you want to get more information about the XPS panel for sale, welcome to contact us.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST