E-mail: marketing@hbhuamei.com

EPDM foam, short for Ethylene Propylene Diene Monomer foam, is a versatile material known for its unique combination of properties that make it suitable for a wide range of applications across various industries. From automotive manufacturing to construction, EPDM foam has gained popularity due to its resilience, weather resistance, and thermal insulation capabilities. Understanding the characteristics and uses of EPDM foam sheds light on its importance in modern engineering and design.

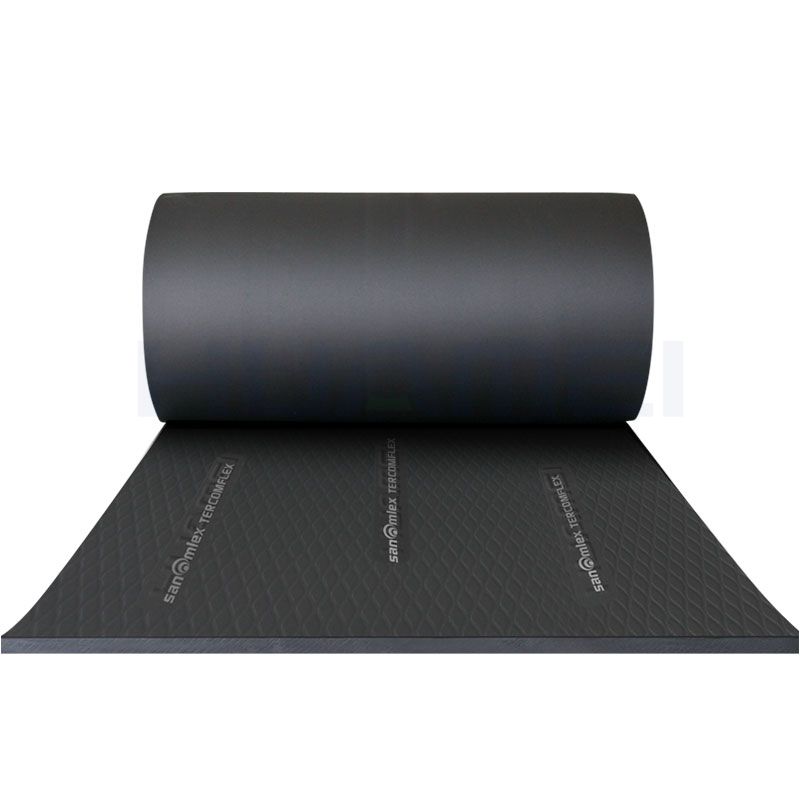

EPDM foam is a type of closed-cell foam composed primarily of ethylene propylene diene monomer rubber, a synthetic elastomer known for its excellent resistance to heat, weathering, and chemicals. The foam is created through a process of polymerization, where the raw EPDM rubber is mixed with blowing agents and vulcanization agents. Under controlled conditions, this mixture expands and forms a cellular structure, resulting in a lightweight, resilient foam material.

Resilience: EPDM foam exhibits remarkable resilience, allowing it to compress and rebound repeatedly without losing its original shape or mechanical properties. This resilience makes it ideal for applications requiring cushioning or shock absorption, such as in automotive seating, gaskets, and insulation pads.

Weather Resistance: EPDM foam is inherently resistant to weathering, UV radiation, and ozone exposure, making it suitable for outdoor applications where prolonged exposure to harsh environmental conditions is expected. This weather resistance ensures long-term durability and performance in applications such as window seals, roofing membranes, and outdoor gaskets.

Thermal Insulation: The closed-cell structure of EPDM foam provides effective thermal insulation properties, helping to reduce heat transfer and energy loss. This makes EPDM foam suitable for insulating HVAC systems, refrigeration units, and building envelopes, contributing to energy efficiency and cost savings.

Chemical Resistance: EPDM foam is resistant to a wide range of chemicals, including acids, alkalis, and solvents, making it suitable for applications where exposure to chemical substances is a concern. This chemical resistance enhances the durability and longevity of EPDM foam in industrial settings, such as sealing gaskets in chemical processing equipment or lining for storage tanks.

Automotive Industry: EPDM foam is widely used in the automotive industry for various applications, including door seals, weather stripping, vibration dampening pads, and interior trim components. Its resilience, weather resistance, and acoustic properties make it an ideal material for enhancing comfort, reducing noise, and ensuring weather-tight seals in vehicles.

Construction and Building Materials: In the construction sector, EPDM foam finds applications in roofing membranes, expansion joints, window seals, and insulation materials. Its weather resistance, thermal insulation properties, and durability make it well-suited for sealing and insulating building envelopes, ensuring energy efficiency and protection against the elements.

Electronics and Appliances: EPDM foam is used in electronics and appliance manufacturing for shock absorption pads, gaskets, seals, and insulation components. Its resilience and cushioning properties help protect delicate electronic components from mechanical shock and vibration, ensuring reliable performance and longevity of electronic devices and appliances.

Marine and Outdoor Equipment: Due to its excellent weather resistance and durability, EPDM foam is utilized in marine applications, such as boat fenders, gaskets, and seals. It is also commonly used in outdoor equipment, such as camping mats, playground surfaces, and sports equipment, where resistance to moisture, UV radiation, and abrasion is essential.

EPDM foam is a versatile material with a wide range of applications across industries due to its resilience, weather resistance, thermal insulation, and chemical resistance properties. From automotive manufacturing to construction, electronics, marine, and outdoor equipment, EPDM foam plays a crucial role in enhancing performance, durability, and reliability in various engineering and design applications. As technological advancements continue to drive innovation in materials science, the versatility and utility of EPDM foam are expected to further expand, contributing to advancements in product design, efficiency, and sustainability.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST