E-mail: marketing@hbhuamei.com

In the advancing world, as it is today, the materials used for insulation are sweepingly trending in terms of acoustics, heat, etc. These form an enhancing part of comfort in the exteriors, interiors, as well as décor. Glass wool is one such insulating material bearing varied applications in homes, be it a part of roofs, false ceilings, or drywalls. According to ‘John Wiley & Sons‘ (Author of Webster’s New World College Dictionary), ‘Glass wool is fine fibres of glass intertwined in a woolly mass, used in filters and as insulation.’

Glass wool is manufactured from borosilicate glass with significant constituents such as silica sand, recycled glass and fixing agents. Glass wool is an insulating material constituted with melted glass as raw material. According to ‘Haimei Zhang‘ (Editor of Building materials in civil engineering), ‘Glass wool is a fibrous material made from the melted glass raw materials or cullet. It is available in two categories: loose wool and superfine wool. The loose yarn is used to make asphalt-bonded glass blanket and glass wool board. Additionally, it is used to preserve heat in the exterior-protected construction and the pipelines.’

Glass wool is created from a thick layer of glass fibres that are cured in an oven at 200°C to bind the strands together and thus reduce the thickness of the sheet. Additionally, it is melted to 1100°C in an electrical furnace and later conditioned in a gas-fired furnace. It is a furnace product made from molten glass. From this melted glass, fibers are spun. This process includes rotating the fused glass at a high speed similar to the methodology used in the production of candy. In the process of spinning, the binding agent is blended into it. No CFCs or HCFCs are developed in the production process. The fibers are gathered in a mat form in a collection chamber and then transferred to an oven where it is cured under controlled conditions to the desired thickness and density. It is tailor-made in rolls or slabs. Likewise, it is also used as a component which is sprayed or applied on the surface to be insulated. It is a versatile material used for the insulation of walls, roofs, and floors. During installation, glass wool should be kept dry at all times because an increase in the moisture content may lead to a significant rise in thermal conductivity.

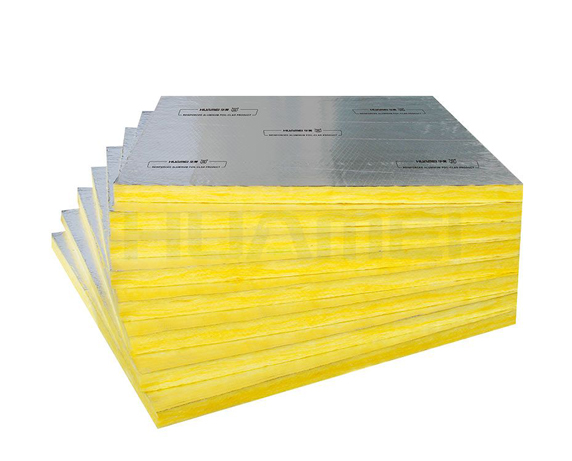

In order to satisfy the special requirements of customers. Huamei group has developed various foil-clad glass wool, solving the problem of damp-proof, sound-absorption, anti-corrosion, fine appearance and processed into various foil-clad product, such as reinforced aluminum foil-clad product, perforated Aluminum foil-clad products .PVC foil-clad products in white and black fiberglass foil-clad blanket. The foil-clad increases the property of anti-broken .so as not to be destroyed and has high intensity of tensile, in addition, ; it also has a fine appearance and was easy to be installed.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST