E-mail: marketing@hbhuamei.com

Many industries deal with substances stored at cryogenic temperatures, such as oxygen, liquid nitrogen, agricultural chemicals, and other industrial gases. Because these substances must be kept at subzero temperatures, choosing the right cryogenic insulation materials is crucial to contain these elements properly. Not only does poor insulation result in operational inefficiency, but it can put the health and safety of workers at risk.

In order to choose the proper cryogenic insulation materials, you need to look at a few key factors:

● Thermal efficiency. The top priority is to prevent the transmission of heat into the pipe from the surrounding air. The insulation material needs to have a low thermal conductivity to prevent heat transfer and ensure a closed-cell structure within the pipe.

● Flexibility. The insulation material must also be flexible enough to mold into the correct shape to fit the piping without damaging the material’s integrity. Flexibility also makes it easier to handle and install, lowering the time and cost of installation.

● Resistance to moisture. The buildup of ice or frost can damage the cryogenic insulation material and the piping system, so the material needs to be moisture-resistant to prevent deterioration.

● Durability. Durability is a major necessity as the insulation material needs to be resistant to wear and tear as well as the chemicals it comes into contact with. The more durable the material, the less you’ll spend on maintenance/replacement.

● Affordability. While not strictly necessary, you want a cryogenic insulation material that is affordable enough to line your piping/tank without breaking the bank. Choose a supplier that is reliable while maintaining prices that fit within your budget.

Potential cryogenic insulation materials include fiberglass, aerogels, polyurethane foam, and cryogenic rubber foam. Each material comes with its own drawbacks–lack of flexibility, high expense, etc–but cryogenic rubber foam stands out among the rest as finding the perfect balance of efficiency, durability, and cost.

Here are just a few of the advantages of cryogenic rubber foam:

1. High thermal efficiency. This insulation material is made from a unique blend of rubber and foam, giving it a closed-cell structure that effectively prevents heat transfer.

2. Durable. Cryogenic rubber foam can withstand all sorts of stressors: wear and tear, chemicals, moisture, UV radiation. It can also handle a large temperature range, holding up under temperatures as low as -200°C (-328°F).

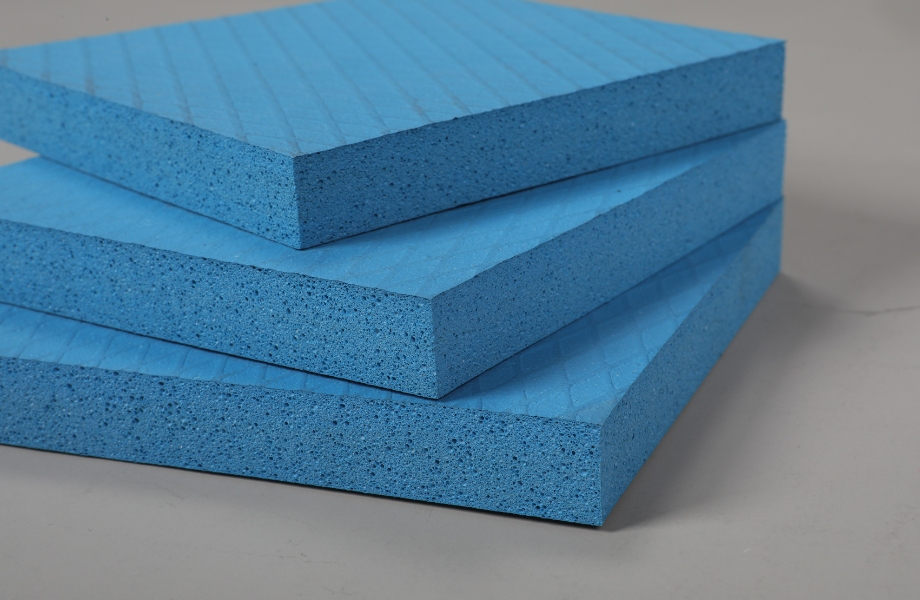

3. Easy to install. Lightweight and flexible, cryogenic rubber foam is sold in sheets that can be easily cut and molded to fit any system. This makes it suitable for many different applications, from cryogenic tanks to pipelines.

4. Affordable. Not only does it come with a cheaper price tag than alternatives like aerogels, its superior insulation properties increase energy efficiency and lower overall costs in the long run.

If you’re looking for a reliable seller of Cryogenic Rubber Foam, look no further. Huamei World is one of the top suppliers of cryogenic rubber foam, creating durable, thermally-efficient cryogenic insulation materials at an affordable cost. Visit us today to browse our selection of rubber foam products and learn more about what we have to offer.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST