E-mail: marketing@hbhuamei.com

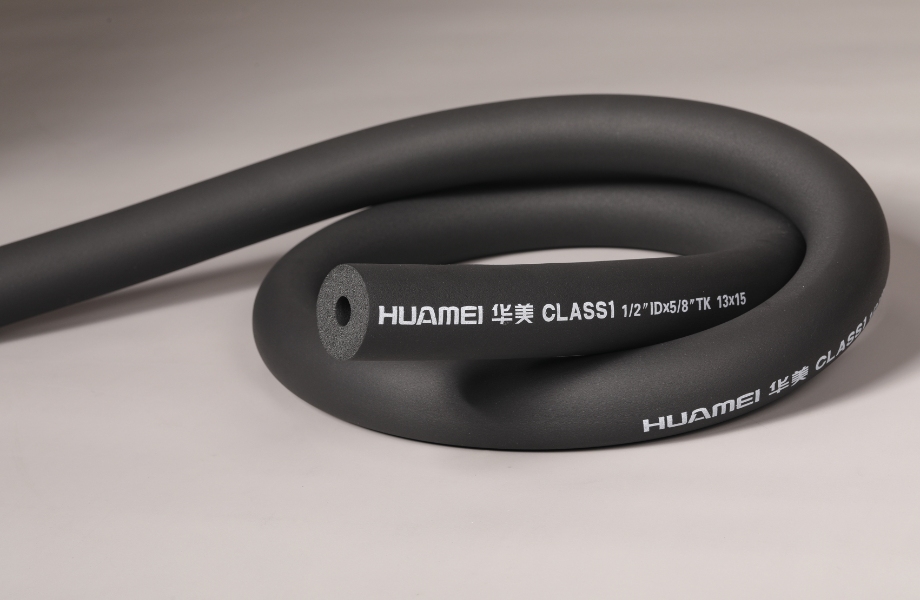

The insulation you choose will affect energy efficiency, thermal performance, and long-term cost savings. While many options are available, Class 1 rubber foam is the best insulation material due to its high thermal resistance, durability, and fire safety rating.

Let us compare insulation materials and discuss why Class 1 rubber foam is no 1 insulation.

When choosing insulation for your home or business, it's essential to know the basics of each material to make an informed decision. There are different varieties of insulation on the market. Each has different behaviors that affect its thermal performance, durability, safety, cost-effectiveness, and more.

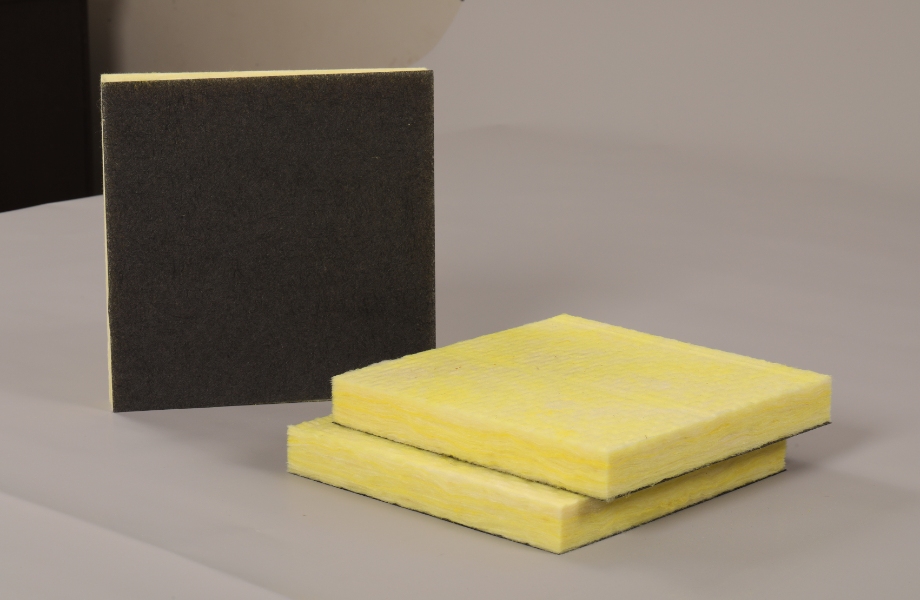

Fiberglass is one of the most famous insulation materials. It consists of tiny glass fibers that come in batts or loose fill. Its popularity comes primarily from its low cost and ease to installation. The material has enough thermal resistance R-2.2 to R-4.3 per inch for many standard applications.

However, fiberglass presents several notable limitations If the installer does not use the proper personal protective equipment, the tiny glass fibers can become airborne and cause skin and respiratory irritation. The material settles down and compresses for a long time, especially in loose-fill applications, reducing its ability to insulate. Moreover, while fiberglass does not burn, it can trap moisture against buildings and cause mold growth in humid areas if not correctly installed with vapor barriers.

Mineral wool is made from molten rock or industrial slag spun into dense fibrous mats. It has several benefits over traditional fiberglass. This material, which can withstand temperatures above 1,800°F without burning up, is considered very valuable for commercial construction where fire ratings are key. Due to its density, mineral wool has better sound-dampening qualities than fiberglass.

These benefits come with some practical challenges due to the increased density. Because it is up to 50% denser than fiberglass, mineral wool is typically 2-3 times more expensive. The rigidness of the mineral wool boards can make installation challenging in areas with irregular framing or many obstacles. Even though it resists moisture better than fiberglass, installation in continuously damp conditions will cause it to fail.

Spray polyurethane foam is a high-tech insulation solution that expands when sprayed, filling every empty space. Available in open-cell and closed-cell formulations, spray foam offers excellent thermal resistance, and closed-cell formulations can achieve an R-value of 6.5 per inch. This expansion property helps create a good air barrier and thus significantly minimize energy loss through draughts and cracks.

Spray foam’s exceptional performance comes with high cost. The cost of spray foam is usually 2 to 3 times more than fiberglass. It is important to have spray foam from a professional because incorrect mixing or installation can cause the foam to shrink, emit volatile organic compounds, or not spread evenly. When properly installed, the material has excellent durability over the long term. But after application, repairing or modifying areas that have insulation becomes much more difficult.

Cellulose insulation is mainly made from recycled paper products treated with fire retardants. It is an eco-friendly alternative to synthetic insulation products. The material can be blown into place to fill irregular cavities and has good absorption qualities because of its dense fibrous structure. Cellulose is a favorite inclusion in many green building projects because it has a high recycled content, with most cellulose having over 80% post-consumer materials.

The most significant difficulty with cellulose insulation is moisture control. The material can get damaged due to water. When the material stays wet for too long, it can become compacted, ineffective and grow mold. While fire retardant treatments make cellulose insulation safer, the material is still more likely to burn than a mineral insulation like rock wool. Cellulose insulation can settle by 20% of installed volume in time, with the potential for gaps in insulation coverage that require additional filling.

Rigid polyurethane foam boards are valuable for applications where space is at a premium because they provide high thermal resistance in thin profiles. With an R-value of 5.6 to 8.0 per inch, the boards provide good insulation efficiency and add to the structural strength of building assemblies. Water doesn’t penetrate the closed cell structure, so there’s no worry here.

The material is flammable, which affects building design. Many applications require additional fire retardant treatments. Thus, installation requires precise cutting and fitting since the rigid boards do not conform easily to irregular spaces. The most expensive insulation material bonded polyurethane board (per sq. ft.) cost remains a key factor.

Every insulation material is best suited for a specific application. Fibreglass is a cheap insulation board that works when not too high insulation levels are fine. Mineral wool is ideal for fire-rated assemblies and sound-sensitive areas. The premium performance of spray foam could be an energy-efficient construction. It is not a DIY installation. Reusable materials, like cellulose, are highly sought after in many green building projects. Where space is a premium, poly boards are valuable insulation materials due to their high R-values.

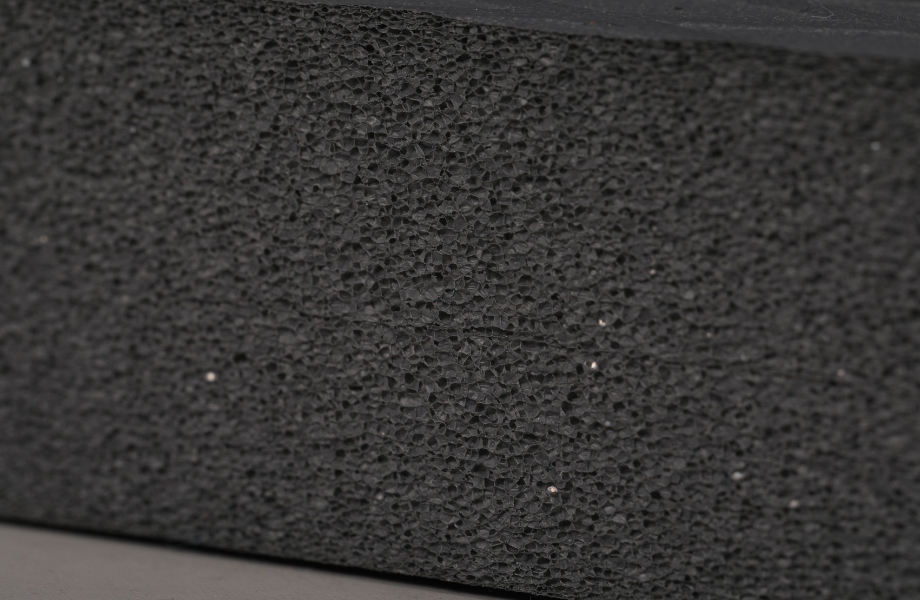

When projects require the best overall performance in heat retention, fire protection, and longevity, Class 1 rubber foam is the best choice as it has the best combination of these materials while avoiding their main downsides.

Class 1 rubber foam outperforms traditional materials with:

● Best thermal efficiency, and one of its most remarkable properties is the R-value of rubber foam.

● Fire Safety Class 1 Fire rated, one of the safest in the market.

● It is resistant to moisture because there’s no water absorption.

● The material will not deteriorate, settle down, or lose its effectiveness.

● Eco-Friendly – Free from harmful VOCs and fully recyclable

Class 1 rubber foam for HVAC, refrigeration, and building insulation ensures energy saving with safety.

For industry-leading insulation, explore Class 1 rubber foam by Huamei. This material is trusted for commercial and residential applications where performance and safety are critical.

While many insulation materials exist, Class 1 rubber foam delivers unmatched efficiency, durability, and fire resistance. Whether for construction, industrial use, or HVAC systems, it’s the best performing insulation material available today.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST